- ZENT Crusher Center

- Jaw Crusher

- JCE Series Jaw Crusher

- Impact Crusher

- Hydraulic Impact Crusher

- Spring Cone Crusher

- CS Series Cone Crusher

- HCS90 Cone Crusher

- Hydraulic Cone Crusher

- VSI Impact Crusher

- VSI5X Impact Crusher

- Mobile Crusher

- ZENT Grinding Mill Center

- Medium Trapezium Mill

- SCM Series Ultrafine Mill

- High Pressure Grinder Mill

- Ball Mill

- Raymond Mill

- LM Vertical Mill

- European Trapezium Mill

- MXB Coarse Powder Mill

- Optional Equipment Center

- Vibrating Feeder

- Vibrating Screen

- Belt Conveyor

- Sand Washing Machine

- Find it Fast

- About ZENT

- Our Service

- Online Purchase

- ZENT Gallery

- Knowledge Hall

- Contact Us Qquickly

>Products>Stone Crusher>Impact Crusher

>Products>Stone Crusher>Impact Crusher

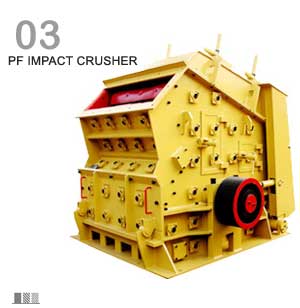

Impact Crusher

Overview of Impact Crusher:

The ZENT PF series impact crusher is a new product by absorbing advanced technologies from home and abroad. The impact crusher is ideal choice for crushing and screening. The most outstanding advantage of this impact crusher is that its finished power is in good, cubic shape and without tensility and cranny. So the final products of the impact crusher is ideal used in highway and railway surface as well as water and electricity industry.

The application of Impact Crusher:

ZENT Impact crusher is optimized and widely applied in the primary and secondary crushing process. This impact crusher is applicable for various coarse, medium, fine materials( such as granite, limestone, concrete, basalt, bluestone etc.), whose grain size not exceeding 500mm and compression strength not higher than 360Mpa. ZENT impact crusher is widely applied in mining and construction, transportation, energy and chemical industry.

Impact crusher can be used in ballast crushing plant, bauxite crushing plant, cement production line, chrome mining plant, coal crushing plant, iron ore crushing plant, etc.

Features and benefits of Impact Crusher:

1. The hammer of the impact crusher is made of high chromium cast iron.

2. Impact liner plate is made of wearable materials.

3. The impact crusher is with unique structure, keyless connection.

4. The impact crusher is more suitable for crushing hard rock with environmental protection and high efficiency.

5. Final product of the impact crusher is in the shape of a cube; the discharge grain size is adjustable to simplify the crushing circuit.

6. Easy maintenance and reliable performance.

7. Hydraulic or hand opening ,either way is possible

Working principle of Impact Crusher:

ZENT impact crusher use the impact energy to break rock or other materials. When the impact crusher works, the motor drives the rotor where the plate hammers fixed rotate with high speed.The raw materials are crushed in the crushing cavity.And the high-speed rotating rotor casts the crushed materials along tangential direction to impact plate at the other end of the crushing cavity. The materials are crushed again, and then, they return to the plate hammer to undergo the process above repeatedly. The materials are bumping with each other when being sent between the plate hammer and the impact plate. The materials become cracked, loose and then comminuted by knocking by the plate hammer, impact with impact plate and bump between materials. The materials with grain size smaller than the gap between impact plate and plate hammer will be discharged.

Impact Crusher Technical Data:

| Model | Spec.(mm) | Feeder Opening(mm) | Max. Feeding Size (mm) | Crushing Capacity(t/h) | Motor Power(KW) | Weight(t) | Overall Dimension(L×W×H)(mm) |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | 55-75 | 12.6 | 2440×2250×2630 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-120 | 110-132 | 14 | 2700×2340×2870 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-160 | 132-160 | 18.6 | 2700×2440×2900 |

| PF-1315 | Φ1300×1500 | 860×1520 | 350 | 160-260 | 180-260 | 24.2 | 2860×2800×3050 |

| PFV-1010 | Φ1000×1050 | 400×1080 | 350 | 60-100 | 55-75 | 13.2 | 2400×2250×2660 |

| PFV-1210 | Φ1250×1050 | 400×1080 | 350 | 70-150 | 110-132 | 15.2 | 2690×2338×2890 |

| PFV-1214 | Φ1250×1400 | 400×1430 | 350 | 100-200 | 132-160 | 18.6 | 2690×2688×2890 |

| PFV-1315 | Φ1320×1500 | 860×1520 | 350 | 150-300 | 180-220 | 24.5 | 3096×3273×2667 |